Search This Site

1: Help with 460 build

1: Help with 460 build

2: OLD SCJ flow numbers

2: OLD SCJ flow numbers

3: New SCJ flow numbers

3: New SCJ flow numbers

25: Header evac

25: Header evac

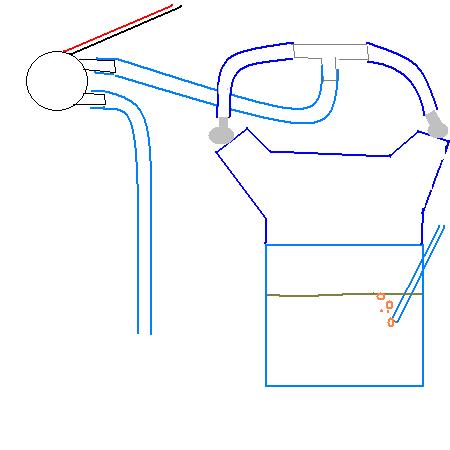

Note, I have seen header evacs used with mixed results, same with useing a cheap vaccum pump set up. Last problem was solved useing a real wet sump vacum pump from aerospace. But, here are some pics of setups that I have seen work.

There is some discussion below about this angle, I have done two of these that did work, one that did not, take it for what it is.

This setup was tried with a new Corvette pump, it seemed to do allright, dont think the engine was sealed up well enough, it would still blow the dipstick at max rpm.

A:------------------------------------------------------------------

Evac. pumps and collector tubes for dummies

July 10 2002 at 2:54 AM

Gordon

I understand the theory behind both, vacuum pumps and collector

'suction' tubes but is either one actually a practical system for a

street machine? I see a lot of both, but sometimes people do things

more for appearance and the 'in' thing rather than for practicality.

As far as a evac pump system, what is consisted in a typical system.

What is the estimated cost for a complete system and are there any

salvage yard pieces that can be used? I realize that there are

probably a lot of variables but I'm talking about something for a

moderately built street car.

Thanks, Gordon

Author Reply

Mark McKeown

Re: Evac. pumps and collector tubes for dummies

July 10 2002, 11:42 AM

BBF truck pumps work well, plumbing is very straight forward. Plumb

outlet to a catch can. If the engine is not sealed tight you will

just suck in a lot of uotside air with no advantage. On our engines

that pull high pan vac you can here the air entering the engine for

a good 20 seconds after the engine has stopped running. A single

retightening of the valve covers can yeild 5"hg if tha vac seems

low.

Standard type crank seals usually don't like to hold much vaccum

since they were originally designed to keep oil and air in the

engine as opposed to keeping air from entering the engine.

Mark J.

Full Exhaust with Pan Evac.....

July 10 2002, 4:59 PM

..does not work well due to the backpressure caused by a street type

exhaust. I run the Vac pump sold thru SVO or who ever they call

themselves these days. It is a truck pump & does quite well. If you

use a good oil/ air seperater it will last & last. MIne is a race

application. Hope this helps.

Mark J

georged

Ful Exhaust

July 10 2002, 7:52 PM

Are you saying that even with straight thru mufflers off of tube

headers there's too much back pressure to utilize the evac with

piped bungs in the collectors?

Jacko

Evac. systems

July 11 2002, 4:36 PM

I run Moroso rocker evac. pipes into the collecters on my street

car. They work, the system is dual 3 1/2" with homemade Flowmaster

copied mufflers. When the pipes come off at the track there is oil

in the collecter but not too much. It pulls enough vacuum to stop

the dipstick lifting etc at the top end.

georged

Evac systems

July 12 2002, 8:49 AM

Thanks Jacko. That sounds right to me as it's pulling an oil fog. As

oil and air never actually mix, most of the air would disappear upon

hitting the collector heat (with attached exhaust pipes), leaving

traces of oil in the collector.

Chad

Collector tubes with full exhaust.

July 12 2002, 9:43 AM

The tubes may have worked for Jacko but I have seen them not work

with full exhaust. His exhaust system is 3.5 inches so that may be

one reason it works in his case. On a street car I would lean more

towards the evac. pump.

Gordon

Thanks for the input guys. n/m

July 13 2002, 10:06 PM

n/m

B:------------------------------------------------------------------

Egr or Pan evac or vacuum pump????

October 30 2003 at 8:49 AM

Michael

Folks,

Finally putting the finishing touches on my Street/Strip BBF. The

engine builder has recommended that I not just run breathers in the

valve covers and that I get set up with something to create some

vacuum in the engine.

My first question is if I run a pan evac system plumbed down to the

headers, will the benefits be destroyed if I run mufflers?

http://www.dragstuff.com/techarticles/vacuum-pumps.html

Are any of you running vacuum pumps (and if so, whose?) on your

street/strip cars?

What would you recommend i run?

-Michael

Author Reply

Kurt

Pan evac

October 30 2003, 4:21 PM

I wonder if you could plumb the pan-evac into the muffler outlet

instead of the header collector??

Seth

Naw, it will work fine.

October 30 2003, 5:11 PM

I just put on the miloden crankcase evac kit this weekend. Welded

the bung into each collector, its a piece of cake to hook up. I run

mufflers, and even at idle I felt a decent suction coming through

the hose...which would pick up even more at speed. I'm real happy

with it. Besides better ring seal and less noxious sludge build up,

I'm sure I picked up another 30hp (j/k).

Michael

Vacuum

October 30 2003, 10:09 PM

It would be interesting to plumb a vacuum gauge into your valve

cover to see how much vacuum your crankcase evac system is actually

drawing. Even at low vacuum your evac is still reducing crankcase

pressure and fumes, which is always beneficial.

To get the most HP benefits, seem to come when you can subject your

crankcase to about 15 inches of vacuum.

My power brake vacuum pump creates over 20 inches of vacuum, to use

that I would need to step it down. Any thoughts on how to do that?

Then I would need to use and Oil/Water seperator tank, so no fluid

gets to the pump.

-Michael

C:------------------------------------------------------------------

Header evac tube questions.

February 13 2004 at 9:21 AM

PullinBret

As everyone knows, header evac tubes work. Has anyone ever put two

on each header and y'd them together to produce more vacuum? Will

this work?

Thanks!

"PULLIN FOR CHRIST" Bret

Author Reply

DaveMcLain

More volume, same peak pressure...

February 13 2004, 9:29 AM

I think it would probably pull more volume, but the peak pressures

would probably be the same. Unless that increased volume was needed

to help offset a bad leaker.

Charlie Evans

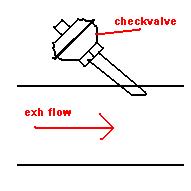

Don't Weld the Tubes in Backwards

February 13 2004, 8:27 PM

Brett,

If my memory serves me correctly, Moroso's or Mr. Gasket's

directions/diagram is WRONG! The open side of the angle cut needs to

be facing the rear of the collector towards the open end. It does

not need to be parallel with the flow and of course not facing the

flow. Believe it or not, I've seen them welded in, turned the wrong

way, a dozen times.

Charlie

PullinBret

Yeah, I'll angle them so as to build pressure...

February 13 2004, 8:43 PM

in the crankcase better, maybe it'll have more compression! Don't it

work that way? Naa, just kidding. I make my own tubes and buy the

check valves separate.

So what's your thought on doubling them up? Hmmm?

"PULLIN FOR CHRIST" Bret

Dennis

Now ya tell me

February 13 2004, 8:47 PM

I thought it was backwards when I put mine in but followed the

directions.I'll be cutting them back out and turning them

around.Thanks for the info.

PullinBret

DENNIS, what'd ya do that for?

February 13 2004, 8:52 PM

I made mine out of regular black pipe. Cut an angle on the pipe and

then cut a small approximate 90* angle to that and face the short

cut to the back, then do a little fine tuning with a grinder. That

is harder to expain than it looks. Hmm, I guess a pic is worth a

thousand words.

I'm just teasing you Dennis!

"PULLIN FOR CHRIST" Bret

Dennis

Re: DENNIS, what'd ya do that for?

February 13 2004, 9:13 PM

I do things like that so I will always have something to fix. Why

didn't you tell me they were backwards when you looked at them?

LOL!!

PullinBret

Should'a known it would be my fault!

February 13 2004, 9:27 PM

I guess I did look at them didn't I? Wasn't it pretty cold out? Er,

uh, something like that.

"PULLIN FOR CHRIST" Bret

Charlie Evans

Who's Directions?

February 13 2004, 9:46 PM

Dennis,

Who's directions where they? Moroso, Mr Gasket or ? I've forgotten.

Charlie

Dennis

Mr.Gasket

February 13 2004, 11:30 PM

n/m

Randy Malik

Angles

February 13 2004, 11:47 PM

I think you'd be surprized at the vaccuum signals and how their

strength changes by how these tube openings face.

I have tried different positions on a running engine on the dyno and

found some INTERESTING results as to not only the direction of the

opening but also their position fore and aft. The opening angle

changes as the position in the collector changes. Opemings directly

rearward, openings toward the side and openings directly parallel to

the exhaust flow were ALL favorable depending on where and what

angle the tube was installed. There seems to be NO real correct way

without testing each individual settup.

D:------------------------------------------------------------------

What kind of HP gains with a nice vacuum pump...

August 26 2003 at 10:39 PM

PullinBret

over the header evac. system? anybody got any comparisons?

"PULLIN FOR CHRIST" Bret

Author Reply

Reddog

may have

August 27 2003, 9:28 AM

some info for you soon Bret, if we get it all mounted we will pull

with it friday. All said and done, it will have cost 800.00. Haveing

a little trouble finding anyone with experience with them, wondering

also if it would not be better to go ahead and run a dry sump, as I

believe I was told here that you dont have to run a vac pump with

dry sump, but an engine builder here runs both on his TWD, and also

the directions with the pump mentions it as well. ANYWAY, I 'll let

you know Late SAt or sunday how it FELT sounded and looked. May help

you decide.

Dave McLain

Evac Horsepower

August 27 2003, 1:58 PM

I have not tested a vac pump instalation on my dyno to see how much

it helps or hurts, but I did test a Moroso evac kit and it was worth

about 15 horsepower on a 630 horsepower 557 with no other changes,

that's alot in my opinion. Question is, you'll spend alot on a vac

pump setup, but will it gain 15 horsepower for every $50 spent?? I

doubt it! Here's a good one, has anyone ever run multiple evac

systems on an engine, ie. two or more check valves in each

collector, two hoses to a junction block on the firewall etc??

I have a nice vac pump from a 351 Ford that I'm going to mount on a

bracket to allow for easy instalation on my dyno. I want it to be

able to work on any engine with a single V belt. It'll be

interesting to see how it helps with a given amount of depression,

since it takes horsepower to drive the pump it's probably a road of

deminishing returns. I'll post my results after I put this to the

test, could be really interesting.

David

Vacuum pumps do increase power, but....

August 27 2003, 2:56 PM

Kaase told me that to much vacuum can cause oil pump cavitation. I

also found the same thing at the Reher/Morrison website under the

tech articles. They both say that the vacuum is trying to pull oil

from the pickup, making it harder to pump. I guess as long as you

got good oil pressure, it's nothing to worry about. I want to run

one on mine, too. Racinray runs one and he drains a fair amount of

water out of his catch can after every run. Dave

Gary Blair

Peterson has a good set-up. It's a wet sump/vacuum pump combo.

August 27 2003, 3:12 PM

It has four 7/8" vacuum sections along with the pressure section.

The vacuum sections are divided into two pairs with a suction port

for cach pair. You hook one section to each valve cover. It uses a

#16 oil suction to the pan. It runs around $800. This way you get

the best of both worlds.

brian

I run one of those WetVac pumps..

August 27 2003, 5:23 PM

I use it as a 3 stage drysump pump(petersen said thats ok,its a

drysump pump anyway)..it makes about 7-8 inches vacuum going

downtrack on a 512.maybe capable of more,but I have cork v/cover and

pan gaskets....

racinray

HP

August 28 2003, 3:50 PM

Bret not knowing what type fuel or exactly what you are hoping to

accomplish it would be hard to say if the expense is worth it.If HP

is your only goal don't waste the money the increase is very

insignificant.If you run alcohol or run in high humidity then the

moisture extacted is more than worth it.Moroso and Aerospace no

longer have the market cornered.The pump I have cost far less.If you

are interested just post on forum and I will get info for you.

IRSS

Popular HotRodding did a test.....

August 28 2003, 6:23 PM

On a BBC, a 565" inch I think it was. Anyways, they were able to get

37 additional HP from it with no other changes, I think its kinda

significant.

racinray

popular hotrodding

August 28 2003, 8:18 PM

I also read this article and all I'am trying to say is that is a

small amount for the money that it takes to set up a good system.I

have run my car with and without the pump back to back car ran a

5.91 with and 5.92 without that seemed insignificant for the $500.00

it cost to install.Don"t misunderstand am very pleased with the lack

of contamination the engine has since I started using it.But also

believe that small increases on a dyno do not always show at the

track.

Reddog

Anyone experience lower oil pressure

August 29 2003, 1:05 AM

we set it up tonight, while the gauge showed very little vac((we

seemed to have some leaks)) the oil pressure which normally goes to

80 with rpm, only went to 60. Never showed more than 5" of vac. This

is an aerospace pump, driving a little faster 1.8:1 than recomended

1.6:1. Driver is worried. Motor seemed to respond real well when it

had differant headers and evacs. No signs of oil or steam out the

pump exhaust. Did all this in the shop, so not a good test overall.

IRSS

I have heard....

August 29 2003, 1:17 AM

I have heard about people taking the air pumps (or more commonly

called "smog pumps"), and spinning them backwards to create vaccuum,

it only makes about 5-6" (?) of vaccumm, and they claim that it

makes a difference. Its all junkyard stuff, so its very cheap to fab

up a system. If it dont work to satisfactory conditions, then its

not like you'd be out a large sum of money.

Travis Rice

Don't know about true HP numbers but .......

August 29 2003, 11:46 AM

On a 514 with 11.5:1 Compression in a 3845lb car the best Et without

a Vacuum puump was a 10.44 @ 130mph. I ran this combo for

approximatley 3 years and freshened it every other year with rings

and bearings. So this was as fast as I could get the combo to go.

Only refreshened the motor, and added a vacuum pump and went a 10.36

@ 131 on the second pass out. Pump was an Aerospace 3 vane, Sold the

Aerospace and bought a Moroso 4 vane and the car went a 10.22 @ 133.

Aereospace would only pull about 4-5 inches of Vacuum at full

throttle, the Moroso has to be limited with a relief valve and still

pulls 15-16 at full throttle at a slower spin speed on the vacuum

pump.

I think some combo's can really benefit from a Vaccum pump but like

anything else the combo needs to be at it's prime before installing

one. One other note, in my opinion Aerospace just plain sucks ! Not

trying to get a flame started but I have yet to have a good

experience with them, the pump housing will wear out before the

vanes do and thier customer service just stands out like no other

company that I have dealt with before. I also run their brakes

system too but would buy Wilwood given another chance.

E:------------------------------------------------------------------

Crankcase evacuation

August 3 2002 at 9:30 AM

georged

I've reviewed the posts on this subject and the consensus seems to be

split on whether the exhaust header evac systems are effective or not.

I'm not concerned about oil residue from condensation being in the

collectors, but want opinions on if they can do an acceptable job of

relieving crankcase pressures.

There are lots of photos posted here with high-dollar engines having

just breather caps on the valve covers, with no pump/exhaust evac, PVC

setup, or other obvious method of relieving pressure. What are you

guys using? Anything?

Any advice will be greatly appreciated.

Author Reply

Kyle J

PVC

August 3 2002, 10:08 AM

I run a 800 HP BBF (Drag Racing) and only use a large hose tapped into

the intake from the PCV Valve on the vavle cover and have never had a

problem. The oil filler breather cap on the other valve cover has been

siliconed shut except for 2 of the small holes in it. Seems to work

fine. Good luck with it --

Randy598

Re: Crankcase evacuation

August 3 2002, 12:09 PM

I run the header evac. on my race car (changing over to vac. pump and

dry sump) and my street car. Whatever you decide it is my opinion that

on a street/strip application you must run some sort of PVC system, I

don't like just breathers in the valve covers. You must draw the

blowby out of the engine in some fashion to reduce crankcase pressure

and oil leaks, whether it be by header vac, intake vac or a

combonation of the two, or vac. pump.

Intake style will have stronger signal at idle than WOT (but your

contaminating your intake charge)

Header style will be opposite, weak at idle but strong at WOT. (but

your contaminating the atmosphere) You could run the two styles

together with a "T" that way you have signal at all times.

Vac. pump will work at all RPMs and throttle positions and the reside

is collected in a breather tank.

Randy

georged

Methods

August 3 2002, 1:04 PM

I agree the pump is ideal, I just don't want to spend the bucks as it

isn't a dedicated race engine. Nor do I want to contaminate the intake

mixture, so I'll stay with the header evac system. Randy, did you

place both breathers at the front of the valve covers on your street

engine to avoid the natural buildup of oil at the back? I'm using Ford

Racing valve covers and haven't cut them.

Many thanks,

George

Randy598

Breather location

August 3 2002, 1:27 PM

Street car has one at each end (stock FE pentroof covers)and full

lenght exhaust with tail pipes (3 inch all the way!)works great.

Randy

georged

RE: Breather location

August 3 2002, 1:33 PM

Ahhhh... So you run two from each valve cover? T them into one bung

each side or two collector bungs each side?

Randy598

Re: RE: Breather location

August 3 2002, 1:44 PM

Just one from each valve cover. Passenger side it's at back, driver

side at front of cover. Sorry for the confusion.

Randy

Anonymous

FE valve covers

August 3 2002, 5:38 PM

I haven't touched an FE in years and don't remember what the covers

look like. In any event, do the FE covers fit a 385?

Thanks, Kevin

Trevor C.

FE valve cover won't work on 429/460 engine. n/m

August 3 2002, 7:11 PM

georged

Valve covers and thanks

August 3 2002, 8:54 PM

As mentioned, I'm using the tall Ford Racing valve covers made for the

385, so FE fit won't be a concern. My thoughts were on breather

placement, and as cast iron 385 heads have a tendency to gather

drainback oil at the rear of the valve covers under hard acceleration,

I was wondering if the Edelbrock RPMs have that same situation. I

can't inspect the RPM drains, as they're on B/O, shipping the week of

8/5, so if they're the same drain as the cast iron heads, maybe some

valve cover baffle adjustment is in order. With stock valve covers,

that may be the reason some people are finding oil in their header

collectors. Scott has a set of RPMs but I don't think he has them

installed.

Thanks to all.

Randy598

Valve covers and drain back alignment

August 3 2002, 9:40 PM

On the race car, the 466 that was in there was equipped with a pair of

iron CJ heads. The breathers were both at the back of a pair of sheet

metal covers with no baffels under breathers. Covers are very very low

and I had no oiling in headers, but a pair of oil deflecter would be a

good idea. Don't the tall FRPP covers come with a pair of deflectors?

I know they used to.

Like I have said many times before I think some of the head drain back

problems are due to a mismatch of the drain holes at the head gasket

joint. Maybe its just me or if this is a bigger problem than me? Would

like to here some feed back on this, has anybody else seen this??

Randy

foxxxmannn

hole alignment

August 4 2002, 11:20 AM

yes the hole alignment is grossly off.

i havent contured it yet but i probly will on the next freshen

my evac trys to suck the rocker cover gasket in where the middle top

bolt is suposed to be,on fms covers those are deleated,so i put a

small 1/4 20 stud(very short)to hold the gasket in place

ROBERT

Gordon

Re: Crankcase evacuation

August 4 2002, 12:01 AM

George, I posted on this subject a few weeks or so ago. I was going to

go the evac. pump route but was talked into the header evac. instead

by some friends. The reasoning was because of exspence, time and ease.

With my motor in the car (late model mustang), I had a lot of room to

run the evac. lines through the K-member to the collectors if I

installed them in the front of the valve covers. If I were to run them

from the back it would have been a very tight fit with the headers

etc.. One benefit is that in my car the engine sits a little high in

the front and that should aid in keeping the oil out of the lines. I

also have the FRP valve covers and using AN bulkhead fittings, you can

use the baffles that come with them. Also makes a nice looking

install. Good luck

Gordon 460 1985 GT

georged

Re: Crankcase evacuation

August 4 2002, 9:39 AM

Gordon, any chance of a picture to my email?

Thanks

Gordon

Re: Re: Crankcase evacuation

August 5 2002, 9:58 AM

Georged, I would be more than happy to get you a picture however my

car is totally disassembled right now. The chassis is getting all the

final paint since the new cage and mini tubbs, the rear end is getting

powder coated, assembled a new lower end this past weekend, all the

engine bay aluminum is getting polished and so on and so on. I

originally thought the car would make Woodward Dream cruise but

absolutely not! Basically my evac. tubes are set up like this: 90 deg.

bulkhead fittings mounted in the front of the valve covers (breather

locations) which utilizes the baffles. Stainless braided lines run

down in front of the K-member behind the spring and into the bungs

located on the outside of the collector. I used a couple of Adel

clamps to hold the lines in place. If you try this, you may have to

get the 90 deg. fittings and Adel clamps from an aviation supplier. Or

give me a shout and I can help you out (I'm an aircraft mechanic)I

have loads of fittings in my box. Good luck, Gordon

Mark

PCV

August 4 2002, 12:10 AM

I use a breather in the drivers side valve cover and use a PCV valve

in the passenger side valve cover with a inline fuel filter in the

between the carb and the PCV valve.I have used this setup for at least

6 years the fuel filter keeps oil from sucking into the carb.

Later Mark.

Scoring disabled. You must be logged in to score posts. Respond to

this message

Randy m

I use e vacs on

August 7 2002, 1:15 AM

my headers.I have expiremented placing the tubes in the collecters in

different places and depths the vacum would suprise you when it is in

the right spot.

GranTorinoMan

Where did you find the best placement?

August 7 2002, 1:22 AM

I've got a closed exhaust, where would you say the best place to weld

in the tube for the evac. system, on my headers?

Anonymous

Re: Where did you find the best placement?

August 7 2002, 3:15 AM

Do you have mufflers?Ihave never ran e vacs on a street car so I have

cant honestley tell you where would be the best place in your

application.I have found the best place on open headers to be about 1"

past where the collecter necks down.A friend of mine turned the

opening of the tubes around towards the wall of the collecters on a

set and he said it would suck the valve cover gaskets in.I built a

vacum pump one time that worked off a 3" water pump.It was a tube that

had a cone in side of it that pressurized water was forced through

with the pump.The cone increases the velocity of the water which

created enough vacum to pump water out of a barge.This was about a 15'

pull I cant hardly beilieve it worked but I saw it with my own

eyes.Everthing has to be in the right place for it to work properly.It

amazes me what air flow can do if properly controlled.

GranTorinoMan

Stock dipstick tube leaks at high RPM

August 7 2002, 10:59 AM

I hate opening the hood and finding the engine bay with a nice coat of

oil on it after every 1/4 mile run. Will the evac system stop this or

is there a good dipstick tube cover that I can buy that will hold the

oil back? Any ideas?

georged

Crankcase pressure

August 7 2002, 11:09 AM

If you seal the dipstick, that pressure will look for another way out,

with seals and gaskets being the easy targets.

A prior post stated the header collector crankcase evac system stopped

his dipstick from being the pressure exit point.

Charlie.

Dipstick blowby

August 7 2002, 1:21 PM

We hook a small spring (like a carb. return spring)through the loop on

the dipstick and through a tab on a water pump bolt. Holds the stick

down tight and is easy to un-hook to read oil level.

GranTorinoMan

Great Idea

August 8 2002, 10:42 AM

I'm going to relocate my header evac pipe, and that spring hold down

is a great idea, thanks!

F:--------------------------------------------------------------------

Crankcase header evac question

December 30 2002 at 2:53 PM

georged

The commercial kits come with no provision for using AN fittings and

ss braided hose. Other than tacking on threaded fittings to the

existing very thin metal fittings, does anyone have a better solution?

Author Reply

Jerry

Shogun makes one

December 30 2002, 2:58 PM

but it's very pricey. It has braided line, AN fittings and a check

valve at the breather.

Jerry

G:--------------------------------------------------------------------

Evac horsepower test..

March 8 2003 at 8:46 PM

Dave McLain

I did some testing this evening on an engine making a little bit over

600 horsepower to see the effects of the evac system that hooks to the

headers via check valves mounted on the collectors. The verdict,

Peak horsepower without 608 at 6200rpm, torque 660 at 4300rpm. With

the evac system hooked up, no other changes, 626 horsepower at 6200rpm

and 676 ft/lbs at 4300rpm. Everything else about the engine was

exactly the same no more than about 2 minutes between runs.

Now I would not want to jump to any conclusions after one isolated

test such as this one, but evacuating the crankcase is obviously worth

at least some horsepower.

This particular engine is a Dove headed 557 with one carburetor. The

oil pan is the Moroso model for a 4 wheel drive truck application with

no windage tray. It's possible that this is an extreme case with 18

horsepower and 10lbs/ft difference.

Author Reply

Kim

Pretty consistant

March 8 2003, 9:28 PM

I think a lot has to do with the amount of blow bye as well as how

sealed everything else is.

25hp is seeming pretty consistant for header evac stuff.

I think a little more could be gotten with more vacume. I wanted to

monitor actual crank case vacume, but the dyno only had one vacume

port and I wanted to monitor the intake for carb efficiency.

Maybe next time Ill take a stand-alone gauge and figure out some sort

of way to at least monitor the vacume. The morroso pump can be

overdriven enough to really pull some vacuum. I saw a difference of

25hp (well then the ehad gasket popped at 1020)

foxxxmannn

Kim,what do you use for an oil seperator,with your pump?

March 9 2003, 10:27 AM

ive read if oil gets into the pump its done.

ROBERT

kim

Haven't run a pump yet

March 9 2003, 12:20 PM

On the dyno we used the header extractors.

I have 2 of the 94 cobra electric evac pumps that are supposed to pull

10" of vacume. Im going to try and avoid another belt driven headache.

The electric pumps are fine so long as the motor is kept above the

impeller, the oil mist isnt a problem. Then expell it into small jas

puke cans with a breather.

dcrahn

Dave, can you post a diagram?

March 9 2003, 8:27 AM

I think I understand what you are talking about but, like they say a

picture is worth a thousand words.

Dave McLain

Not much to the system

March 9 2003, 10:03 AM

There really isn't anything at all to the system I tested. It's just

two check valves, one in each collector, a piece of 5/8 hose and two

oil separators that look like they came from a Mopar 360 from back in

the late '70's. This kit was a Mr Gasket, but it looks just about

identical to the Moroso.

There was nothing tricky about how the pipes enter the collector or

anything. I do want to rig up something with a guage to see how much

depression it can muster, but I would say it could be a couple of

inches hg.

foxxxmannn

at idle, 1200 rpm the mopar breather will leave a kicky on my hand

after about 10 seconds

March 9 2003, 10:07 AM

n/m

ROBERT

Dave McLain

No kidding??

March 9 2003, 10:16 AM

I'm going to T into the line somewhere and connect my dyno vac guage

to see what it's doing. It seems to help power from just below the

torque peak on up on this engine. I was really suprised that it made

that kind of an improvement and this is a very tight engine with

little to no visible blowby under load.

foxxxmannn

i bet you get at least 6-8 inches n/m

March 9 2003, 10:23 AM

n/m

ROBERT

randy

vacuum on a blower

March 9 2003, 5:13 PM

i have my pvc line from the valve cover under the carbs on my 8-71

blower and the vac/boost gauge showes anywhere from 10 to 15 vac at

cruise. i guess i need a vac gauge at the carb base to see what it

would be at full throttle.

i guess if i put my car on a dyno and pulled the line off on one of

the pulls it should make a noticable hp gain.

kim

big difference between the vacume at the carb and vac in case

March 9 2003, 7:05 PM

Your supplying 15in or whatever vacume source to a 3/8" hose to the

case, but you do not have 15" vacuum in the crankcase. Your

measurement at the base of the carbs would be the difference between

the demand of the blower and the ability of the carbs to meet that

demand. 15" of vacuum is pretty bad for a race car, but pretty

economical for a street car.

At WOT, on my NA engine Im ceeping close to 1" of vacume at 8000 RPM.

From crack of the throttle till about 7500 RPM the manifold vacume is

.7".

If your running a PCV system and an open breather element odds are

your crankase is under pressure most of the time, to maybe dropping to

atmospheric, pressure when the PCV valve is open.

To run an honest crankcase vacume, no open sources that can be helped,

and it will take a pretty good vacume source to move all the

displacment of the engine out of the crankcase, as well as continue to

pull all the blow-bye out of a loose race engine.

Reddog

Heeders to pump, worth it?

March 25 2003, 7:24 PM

Owner wants me to find an OEM pump that we can get from the yard to

replace the heeder evacs. Any suggestions? Electric would be great,

but we could with work run it of the crank(8000rpm). Anyone know any

make/model stuff to look for? Or are we getting enough from heeders

not to worry?

Paul

belt driven Vacuum system

March 25 2003, 8:51 PM

We done a flat top 598 with a mild roller cam and a set of C heads. we

installed a steffs vacuum system. At 1200 RPMs we ran it at 6 incn

vac. at 6000 it has 14 in. We Dynoed the engine on Kaase's dyno.

started recording at 4000 and pulled it to 7200. without the tank cap

at 6800 it pulled 961. 3 pulls never, shut the engine off. snapped the

cans lid back on 2 pulls at 984@6800. The #s were 20 more straight

down the chart. the most impressive though was watching the oil

pressure stabalize at a higher RPM. I race some now that are using a

smog pump to valve cover and running the breather hose in some sort of

homemade catch can. Don't know how much vacuum they pull or even if it

works well or not. We run crankcase vacuum gauges on all of our

nitrous motors, it will tell you instantly if you have hurt a piston

or rings before you make another pass. But if you gained 20 with a

evac system, thats great and the next one I do I'll save $1800 on the

steffs and try your setup.

Mark McKeown

Very similar results

March 25 2003, 10:25 PM

Dave, Ive tested NHRA AS/A engines in A-B-A testing with very similar

results. I've seen 13-22 hp with a evac or small pump.

Mark McKeown

McKeown Motorsport Engineering, Inc.

http://mmeracing.com

larry

Any one ever hooked up electric vacuum pump via the fuel pump block

off plate?

March 28 2003, 7:58 AM

I am planning on hooking one there and see what the results are.

larry

Here is a link to the vacuum pump I am going to use....

March 28 2003, 8:10 AM

http://www.mustangsandmore.com/ubb/Forum12/HTML/003294.html

Jerry

Electric EVAC Pump

March 30 2003, 12:02 AM

Larry, We bought one!, OR shall I say Jeff bought one and HE was the

genuiea pig. Tried it out on the Cougar and it Works. Not real sure if

it helped his ET or not but it stopped a small oil leak. I have to go

by his shop and measure how much vacuum it pulls, haven't done that

yet. BUT first observations are IT WORKS!

foxxxmannn

2001 2002 taurus also use an electric pump

March 30 2003, 10:31 AM

its below the batt tray mounted on the sub frame

ROBERT

Mark McKeown

Better location

April 8 2003, 9:58 AM

I think I would search for a better place to connect to pump. The fuel

pump location will more than likely pull alot of oil.

Mark McKeown

BCR

Well I tried this out

March 30 2003, 11:48 AM

at the track last Sunday. I hooked 3/4 hose from each valve cover to

header collecters clamped to a short piece of tube welded at an angle

toward rear, results were NO oil around twist in breathers, (usually

is), car ran .02 faster than it ever has, not once but 4 passes,oil

stayed cleaner, (alky), also I cant attribute this to the evac. tubes

but most everyone that I spoke to said their cars were running about a

tenth slower than last week, mine was .04 to .06 faster than the

previous race & as I said .02 faster than it ever has, all for a

little welding & scrap hose.

Reddog

BCR if that worked for you try this

March 30 2003, 12:25 PM

if you did not use a check valve at the collectors, your vaccum was

not constant, I have done this as well. But if you want to do it from

scrap, get you two check valves and but them on the pipe coming out of

the collectors. I have taken them from 350's they are right above the

exhaust manifolds in the smog pump pumbing, and some have three. Also

got a set off a 92 tempo/topaz, but they are under the engine toward

the back, a car with the engine out would be easy to get. Check them

to make sure you can blow through them one way, but not the other.

Install them so you can blow toward the collector, but not back toward

the valve covers. This will allow the exhaust to draw vaccum with out

pulsing and at times pressurizing the crankcase.

BCR

I already have um

March 30 2003, 1:26 PM

I just havent put them on yet. Question! When you blow thru it , seems

to take a little press. to crack it open, wouldnt it have to build

some crankcase press. in order to open the check valve? Although it

only takes minimal vacuum to open from other side,I assume this

working from both sides would not allow press to be in crankcase? I

will try them & see what happens. Even if Richard Head Alex from M&M

says my engine cant possibly have that much HP. Richard Head? Whats

the nickname for Richard? Now you get it! BTW my headers are like me &

the rest of my car - unusual, they have 2 in pri & 5 in collecters.

Reddog

no they

March 30 2003, 1:57 PM

are opened by the vaccum in the exh. before you put them on (check

valves) start er up and put your hand over the hose at the vlave

cover. Get a feel for it, than put the valves on and do it again, you

will notice a big increase in the suction it has on your hand. Well I

did when I made my own set anyway.

BCR

Thanks

March 30 2003, 2:03 PM

Hands on proof is where its at! Now thats what I'm talkin bout!

Reddog

pump vs evac #'s

March 30 2003, 12:27 PM

still wondering about the differances in numbers, and if we should

replace the header evacs with an electric or engine driven pump on the

472cid

JS

electric vacuum pump

April 5 2003, 1:07 AM

vacuum gauge measured 4" of HG using the GM electric pump. What is the

amount of vacuum that is best?

Rick

Header evac. on mild BBF

April 7 2003, 12:51 PM

These header evac systems sure seem to offer great benefits at low

cost. Are these systems only truely useful on high-end mega horsepower

setups? Or would it have similar(but smaller) benefits for my

relatively mild (appx 400 hp) 466 in low 12 sec. street and strip car?

Are there any drawbacks? Seems like a win-win situation even at my

level.

Dave McLain

Evac results

April 7 2003, 12:56 PM

I see no reason why the header evac system would not be equally

effective on a lower horsepower application. It seemed to help across

the entire powerband when tested here on my dyno.

I really do not know about the long term effects if there are any,

questions about valve stem oiling, seals etc. I really doubt there

will be a problem with the header system, a vac pump might be able to

do such a good job that valve stem siezure might become an issue.

David Cole

Electric Vac pump?

April 9 2003, 7:06 PM

I was at the NMRA race over the weekend. One of the swap meet vendors

had a Ford electric vac pump. It looked similar in size and shape to

the GM pumps. It was used and he was asking $100 for it. A little

pricey I thought for a used pump.

I wrote down the part # F6ZE 9A486-DL

Does anyone know what the original application is and how much vac

this pump would pull or any other details? Price?

kim

Thats the electric Cobra Evac pump

April 9 2003, 9:20 PM

Pulls 10" vacuum on the 5.4l blown Cobra engine. It was also used on

other models. Im going to try 2 of them.....

H:--------------------------------------------------------------------

100: Electric Fans

100: Electric Fans

A:------------------------------------------------------------------

fans?

February 1 2002 at 4:05 PM

cal

I'm wanting to install an electric fan on my mild 460 mud drag

truck. I looked at some rapid cool fans at the local parts store and

the box side that that they weren't recomemded for a 460 even

running two 14 inch fan..!! Is there a electric fan that will cool a

460? And that won't break the bank? feedback!

cal

Rick

My best shot

February 2 2002, 2:18 AM

I hate to see a post go unanswered so.... I don't see what

difference a 460 has to do with an electric fan. I know they are

hard to cool, even with aluminum heads. I personally would use the

largest diameter fan I can find & be sure to use a shroud. Let us

know if you're successful.

Ken

Already answered in your last post

February 2 2002, 8:13 AM

Chrysler K-car or Cavalier

randy598

RE: fans

February 2 2002, 5:18 PM

Any O.E.M. tubro car with electric fan are usually pretty good. The

Thunderbird turbo coup has an excellent fan, just check your local

junk yard.

Good luck.

Rick

I have one!

February 2 2002, 5:28 PM

If you want to try one

B:-----------------------------------------------------------------

How much radiator for 460 in 69 mustang??

February 3 2002 at 9:27 PM

Dwyan

I am putting out 600hp at rear wheel and would like to get enough

cooling to drive it street legal in 90 degree, high humdity weather.

I am currently using a 19X26" aluminum "Be Cool". It is in the stock

location and is good for only 1 quarter mile pass at the local drag

strip before cool down..... much less a street drive to the local

car show through a couple of stop lights. The original 3 core was

about the same. What size radiator do I need to keep this motor

running cool?? I also run a 14" perma cool fan(2100-2900cfm

rating)with a moroso electric pump. Any suggestions? Thanks for your

input.Dwyan

gregaust

more fan

February 4 2002, 4:50 AM

I have had good success using a 31x19 alum rad with 2x1"tube core.I

tried a few fans but ended up using a factory 7 blade flex fan + a

permacool fan with the 6 alloy blades @16" diameter.

Just my opinion but i don't think that 1 fan is pulling enough

air..I remember seeing somewhere that a 302 needed something like

3500-4000 cfm to keep cool..

David Kee

It may not be the radiator

February 4 2002, 8:42 AM

Loose the electric pump and go to a belt driven setup with a factory

or flex type fan and a good shroud before you buy another radiator.

Gary

That pump will never make it been there n/p

February 4 2002, 8:49 AM

n/p

Dwyan

Can a pump make that much difference?

February 4 2002, 9:22 PM

I do have a 2 or $300 CNC which I haven't put on yet; I can put a

19X31X2inch aluminum on for about 190 bucks; but I have to cut out

the stock radiator area to make room. With the hood on, there isn't

much room for the air to move out of the way either. I hate to spend

money only to find out I didn't do enough. One company makes a

2-pass radiator but$$$$$$, yet I'll spend what it takes to get it

right the 1st time,..remember I live where its hot and humid most of

the year. I appreciate your input and experience...so feel free to

enlighten me much more :-))).dc

David Kee

Electric Pumps - Electric fans (Long)

February 5 2002, 1:27 AM

Check this out. I have only run my car at the track during the cool

winter months. I have the largest aluminum 1" 2 row radiator that

will fit without a major hack job. I have an electric fan that

almost completely covers the radiator from top to bottom. I have the

high dollar aluminum CSI water pump. I run about 1/4 gallon af

antifreeze in the system to try to keep a handle on corrosion

without getting beat half to death if it spills on the track. Tracks

hate antifreeze because of cleanup time. It's all I can do to get

from the burn out box to the trailer after a full pass without

reaching 190. I even ran down the return road in 4th a few times to

keep it from overheating. I can't imagine pulling out onto the strip

and stopping at a light in traffic. Even though the car is licensed,

inspected and insured.

Toma

Fan

February 5 2002, 3:16 AM

its all in the fan....I had problems until I installed a fan from a

Lincoln MK VIII. That mother is an 18" that flows around the 4000cfm

mark depending on year and model. It draws enough current that I

killed a 40 amp relay, and had to upgrade to a special 75 amp relay.

no word of a lie, I can feel it blowing out my closed cowl

hood....no problmes since I installed it....

Anonymous

Alternator size

February 5 2002, 8:35 AM

The last time I found fans that pulled that many amps I had to put

on a 100amp alternator the parts house got tired of replaceing them

for free the 3rd time. Running around in the city at night was just

to many amps besides I think the alternator pulled harder then a

belt driven fan

Ken, The Outer Limits

overheat?

February 5 2002, 8:45 AM

I read your stuff with interest. Even at almost 15:1 I don't run

that hot. Although I have a time or two because of stuff I did

Like electric driven waterpumps.(not enough volume)

Forgot the seperator plate between the pump and housing.(won't push

water properly)

No thermostat(water doesn't pick up the heat properly)

Put the one head gasket in wrong side front and up. (blocked water

passages)

Too small underdriven pulley (pump doesn't turn fast enough to move

the water.

Solution - External electric inline water pump draws 15 amps, moves

up to 30 gpm and doesn't care what you did to the motor or drives.

Now runnin 13.8:1 in 90 degree weather with a 302 rad and never over

195 degrees

Toma

Running a 3G alternator and Yellow optima

February 5 2002, 12:34 PM

Got a 3G alternator out of a '94 Mustang for $65 from an auto

wreckers, and dished out the $170 for the Yellow deep cycle Optima.

Works like a charm, car never got hot, even during break in (oh, and

I run a Mezierre electicr water pump and no thermostat).

You also wann do everything you can to make sure airflow is

maximized through the rad, and can;t escape around it....seal it to

the front rad support with foam or rubber etc...

Toma

Anonymous

BTW, the 94+ Mustang 3g alternator is 130amp!

February 5 2002, 12:36 PM

And it came on the 94" Mustangs, trucks, vans, Crown Vic etc.... it

will say 3g on it, and should sya 130amps (a very few were only 90

amps)....same alternator, jsut different mount bosses.

Ken, The Outer Limits

check these

February 4 2002, 9:53 AM

Hi

The electric drive is a no-no. Won't move enough water - ever.

Either drive it with the motor or put a real electric water pump on

it. Say 20-30 gpm

Make sure the thermostat works. If not replace it with a washer with

a i" hole in it.

The twelve in ch fan is ok provided you have shrouding. If the fan

is direct up against the rad it will not draw enough air over a

large enough area of the rad.

I used a truck rad in a Granada once, with a lectric fan mounted in

the shroud and a bus booster pump for a water pump and never got

over 190 in any temp.

C:-----------------------------------------------------------------

put 460 in my 68 torino gt need help with water pump and fan

February 20 2002 at 7:14 PM

tom b.

Just installed a 460 in my 68, have run into one unanticipated

problem. Don't have enough room between the water pump and the

radiator for a fan only got about 11/2". I have ordered a set of

dual electric fans to put in front of the radiator but would still

like to install fan between the water pump and radiator even if it

is a 4 or 5 blade nonclutch fan. Presently have 74 460 water pump

installed, does anyone know of a shorter water pump? Alsom used 74

balancer and pulleys perhaps some other set up would work better and

anvice would be appreciated. The rest of the story - 74 460 block -

70 429 thunder jet heads and 70 429 cobra jet exhaust manifolds with

edlbrock performer (for hood clearence) intake and 750 edelbrock

carb. Thanks in advance for any help!

Author Reply

steve

short pump

February 20 2002, 9:07 PM

Try to find a '69 thunderbird pump. They are 1/2 shorter, but, hard

to find

StickBBF

Aftermarket H20 Pumps...?

February 21 2002, 7:36 AM

If the '69 Thunderbird water pump is shorter than a '74 460 water

pump, is it shorter than either the aluminum Edelbrock or Weiand

water pumps?

Anonymous

Re: put 460 in my 68 torino gt need help with water

pump and fan

February 21 2002, 10:49 AM

bb

txmont

pumps and pulleys

February 21 2002, 11:11 AM

A set up from a 68- 69 lincoln 460 or T-bird 429 should work well.

I've got a 460 in my 78 fairmont and use the balancer(has the belt

grooves in it)alt brackets, water pump,fan pulley from a 69 lincoln

along with a smaller diameter non clutch fan with the set up. I also

used the Lincoln rad and shroud and it fit perfectly for clearance.

The later model 460 balancer, pulleys, fan, pump etc, really do

stick out a lot more. The lower inlet on the Lincoln pump is

horizontal, while on the T-bird pump it points downward on an angle,

this may be important when looking for rad hoses etc. I also used

the Lincoln rad, it has the same tanks as the T-bird but is wider

and fit perfectly in the Fairmont. It's sort of an all or nothing

thing, the early/ late model parts don't work well together, ie. the

pulleys will not line up etc. Also I used the spacer from the 69

T-bird behind the balancer, as the Lincoln uses a crank driven ps

pump in this location. This worked fine with the truck timing

cover(no oil dipstick) as I use a rear sump pan. This is a cost

effective alternative, the Lincolns I bought for parts (68, 69

sedans) for next to nothing ($150-$400 ea), and were complete with

running 460's and c-6's.

Watch out for some 68 Lincolns as they still might have a 462, which

is useless for 385 applications. The T-birds or Lincoln MarkIII's

are pricier, even for parts cars.

tom b.

Thanks for the information

February 21 2002, 3:31 PM

Think I solved the problem, was using a 3 pulley crank setup and

really only needed 2. Cut the outside pulley off and moved power

steering back so it ran on what was the middle pulley, then had room

to mount a 18" flex lite fan, hopefuly that along with the 2

electrics pushing will do the job.

D:-----------------------------------------------------------------

460 conversion into 70 Mach1

January 4 2001 at 8:37 PM

Darryl

This is a great forum for engine chat and I'm hoping I can use some

of the info. you guys are passing around in here.

I'd like to install a 460 into a 70 Mach1 that currently has a 351C.

It's a street/strip car. I realize Crites & a few other companies

offer conversion kits, but I'd like to get the real scoop on what's

involved in this swap...from the required parts to the joys of

header installation for a guy with large hands. In addition, I live

in Dallas, Texas where it more often than not is over 100 degrees in

the summer. Can I possibly keep the sucker cool and what temperature

can I expect it will typically run at.

Any and all comments are welcome.

Check out my ride.

http://www.geocities.com/snekrs_mach1

Thanks in advance

Author Reply

Bob M

460 install...

January 4 2001, 9:36 PM

Kit uses stock-type Boss 429 Mustang mounts etc.

Headers should be easier to inst than on my 428 Mach1!!! (anything

is easier than that LOL).

With a thick Griffen radiator and a fan shroud it should stay cool

also.

Go for it !

martin edridge

I did that!

January 5 2001, 12:41 PM

I have done this swop to two '70 Fastbacks, one being my own. I did

not use the kit, so I had to make headers and tinker a few other

bits. Cooling is a problem and the cure is a big rad. Mine is off a

'71 CobraJet and is shortened by about 3" as it's too high to fit a

'70. Keep the big standard fan. Electric fans aren't powerful enough

to keep these cool. I can't help you too much as the kit puts the

engine and box in a different place from mine so there will be

different space issues. The results can be impressive, though! Mine

ran mid elevens at one time (no N20) but I have cut it back to a mid

twelve second car now and it drives sweetly. Your car looks really

clean and nice! Boy would I like a rust free one. I have just spent

the past month welding mine up! Wanna see?

http://www.geocities.com/MotorCity/3380/mocgalry.htm

You'll spot mine HTH

Cheers, Martin.

514 MUSTANG

I FEEL YOUR PAIN

January 8 2001, 1:28 PM

HELLO FROM KANSAS DARRYL.I MADE THE MISTAKE OF GOING TO THE SWAP

MEET AT THE BALLPARK IN ARLINGTON DURING JULY WOW YOUR 100F IS WAY

HOTTER FEELING THEN OURS.A FEW THINGS I HAVE LEARNED TO MAKE 460

LIFE COOLER . THERE IS A BYPASS HOSE FROM THE INTAKE TO THE WATER

PUMP.IN A COLD CLIMATE IT'S THERE TO BLEND HOT WATER WITH CHILLED

WATER.NOW IN DALLAS WHEN IT,S 100 OUT YOU DON'T NEED WATER THAT

HASN'T BEEN COOLED GOING RIGHT BACK IN THE ENGINE.BLOCK IT OFF AND

DRILL HOLES IN YOUR THERMOSTAT TO RELIEF PRESSURE.ALSO VALVE OUT

YOUR HEATER LINES.AN ENGINE OIL COOLER EVEN A CHEAP ONE CAN KNOCK

OUT 10 TO 15 DEGREES.YOU'VE BEEN TOLD ABOUT ELECTRIC FANS THEY JUST

DON'T MOVE THE AIR.JETING CAN MAKE A BIG DIFFERENCES TO.YOU HAVE A

BEAUTIFUL CAR IT'S GOT TO BE HARD TO TAKE SOMETHING THAT NICE APART

GOOD LUCK!

Darryl

It happened again...

January 8 2001, 5:45 PM

I called yet another Mustang Shop, spoke with their resident guru,

and he too said an electric fan will do the job.

It's always easy to provide advice at someone elses' expense and no

matter how clearly I articulate how hot it really gets down here, I

keep getting the same answer. I know I sound like a stubborn fool,

but I've yet to meet someone down here running a street/strip

460/520 setup who can offer "real world" experience.

When I find a vendor who will allow me to return the product

(electric fan) if it doesn't meet the objective of keeping the

engine cool, I'll stop being reluctant, cut a check, and go for it.

However, I believe it will be a cold day in hell before that happens

and I'll next need to concern myself with the engine starting, much

less keeping it cool.

Thanks for the input.

Troy

how much air does a stock fan move?

No score for this post January 9 2001, 10:17 AM

If a high performance electric fan moves 2500 cfm, what does a belt

driven fan move? At idle it isn't very much. An electric would excel

here wouldn't it? I would assume cruise temperature wouldn't be

affected much either. Is the radiator capacity the true limiting

factor? Just some thoughts guys, let me know if I'm full of it.